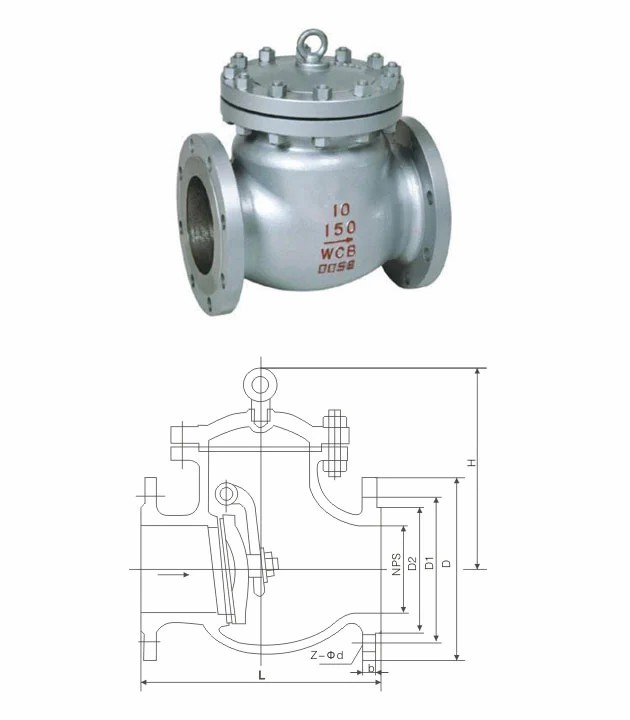

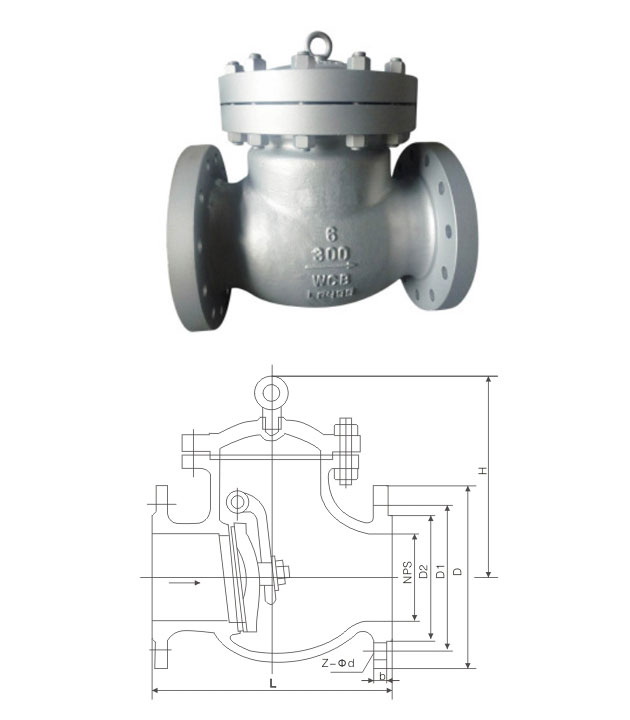

Flanged Check Valve Ss Check Valve

- MOQ:

- 1000pcs

- Size:

- 1/4”-4”

- Payment Terms:

- T/T, L/C, PayPal, Wechat Payment

Product Description

The Swing Check Valve has a flat disc that pivots or swings about a hinge pin. They are low cost, and have low head loss characteristics when fully open. But because of the long stroke and inertia of the disc, the traditional swing check valve may slam in vertical pipe installations. These valves are therefore sometimes outfitted with a lever and weight accessory. They can handle liquids with solids such as waste water.

• Model No. : H44W

• Material: stainless steel

• Connection form: flange

• Usage: flow control

• Seal: Swing dics

• Standard: ANSI, GB

Design Features

• Design standard as per: BS1868,ASME B16.34, GB/T 12236.

• Compact and reasonable product structure, reliable tightness and good performance;

• Smooth fluid passageway and small fluid resistance;

• Swing type disc.

• Can be designed with a Damping Cylinder.

• Rapid closing and flexible actions of the valve disc .

• Small closing impact, water hammer is not liable to be generated.

• Smooth fluid passageway and small fluid resistance.

Product Range

• Body material: carbon steel, stainless steel, alloy steel

• Nominal diameter: 1/2"~40"(DN15~DN1000)

• Pressure range: Class150~2500(PN10~PN420)

• End connection: RF, RTJ, BW

• Working temperature: -196oC~+560oC

Product Parameters

|

Technical standard |

|||||

|

TYPE |

Desubg abd manutacture |

Face to face end to end |

Flange dimension |

Pressure temperature lating |

Inspection and test |

|

Swing check valve |

ANSIB 16.34 |

ANSIB16.10 |

ANSI B16.15 |

ANSI B16.34 |

AP11598 |

|

Lift check valve |

BS 1868 |

||||

|

Chief property and specfication |

||||||

|

(Lb) |

Shell test |

Water seal test |

Air seal test |

|||

|

Mpa |

Lbf/in2 |

Mpa |

Lbf/in2 |

Mpa |

Lbf/in2 |

|

|

150 |

3.1 |

450 |

2.2 |

315 |

0.5~0.7 |

60~ 100 |

|

300 |

7.8 |

1125 |

5.6 |

815 |

||

|

600 |

15.3 |

2225 |

11.2 |

1630 |

||

|

900 |

23.1 |

3350 |

16.8 |

2440 |

||

|

Material list |

|||||

|

Body cover diskhingeside way bush |

Stem |

Sealing shim |

Sealing face |

(C)Working temperature |

Suitable medium |

|

WCB |

2Cr13 |

PTFE Enhanced flexible graphite 1Cr13/Flexible graphite S.S/Acie- proof asbestos tooth profile gashker |

13Cr STL With bodymater rial ptfe Nylon |

≤425 |

Water steam |

|

WC1 |

≤450 |

||||

|

WC6. |

≤540 |

||||

|

WC9 |

≤570 |

||||

|

C5C12 |

≤550 |

||||

|

CF8 |

304 |

≤200 |

Petroleum products |

||

|

CF3 |

316 |

||||

|

CF8M |

304L |

||||

|

CF3M |

316L |

||||

Main Dimension

|

DN |

150Lb 150LbP 150LbR |

|

||||||||

|

mm |

in |

L |

D |

D1 |

D2 |

b |

f |

n-φd |

H |

|

|

50 |

2" |

178 |

152 |

120.7 |

92.1 |

16.3 |

2 |

4-19 |

161 |

|

|

65 |

2-1/2" |

190 |

180 |

139.7 |

104.8 |

17.9 |

2 |

4-19 |

180 |

|

|

80 |

3' |

203 |

190 |

152.4 |

127 |

19.5 |

2 |

4-19 |

190 |

|

|

100 |

4" |

229 |

230 |

190.5 |

157.2 |

24.3 |

2 |

8-19 |

203 |

|

|

125 |

5' |

256 |

255 |

215.9 |

185.7 |

24.3 |

2 |

8-22 |

229 |

|

|

150 |

3" |

394 |

280 |

241.3 |

215.9 |

25.9 |

2 |

8-22 |

257 |

|

|

200 |

8" |

345 |

298.5 |

269.9 |

29 |

2 |

29 |

8-22 |

292 |

|

|

250 |

10" |

533 |

405 |

362 |

323.8 |

30.6 |

2 |

12-26 |

355 |

|

|

300 |

2" |

610 |

485 |

431.8 |

381 |

32.2 |

2 |

12-26 |

396 |

|

|

350 |

14" |

686 |

535 |

476.3 |

412.8 |

35.4 |

2 |

12-29 |

445 |

|

|

400 |

16" |

762 |

595 |

539.8 |

469.9 |

37 |

2 |

16-29 |

490 |

|

|

450 |

18" |

864 |

635 |

577.9 |

533.4 |

40.1 |

2 |

16-32 |

520 |

|

|

500 |

20" |

914 |

700 |

635 |

584.2 |

43.3 |

2 |

20-32 |

546 |

|

|

600 |

24" |

1067 |

815 |

749.3 |

692.2 |

48.1 |

2 |

20-35 |

880 |

|